Since their introduction in the 1970s, modern fog machines have remained among the most commonly used piece of special effects equipment in the entertainment industry; including stage, film & television, and theme parks. Prior to the fog machines we use today, fog & smoke effects were created by incinerating flammable materials such as mineral oil and even used tires.

The history of fog machines is a journey through time, tracing back to the early days of theater and entertainment. These devices, which have become essential tools in various industries, have undergone significant transformations over the years.

The concept of creating artificial fog dates back to ancient times. In theatrical performances of yore, simple techniques like wet straw and torches were used to produce smoke and misty effects. However, these methods were rudimentary and lacked the precision and safety of modern devices.

The 20th century witnessed the birth of the modern fog machine. In the 1920s and 1930s, the first chemical-based fog machines were introduced. These machines used a combination of chemicals, often toxic, to produce thick clouds of smoke. While effective, they posed health risks and were soon replaced by safer alternatives.

In the 1970s, the water-based fog machine was introduced. This innovation marked a significant milestone in fog machine technology. By using a mixture of water and glycol, these machines produced a dense fog that was both safe for inhalation and environmentally friendly.

With the advent of digital technology in the late 20th and early 21st centuries, fog machines became more sophisticated. Digital controls allowed for precise fog output, timing, and dispersion. This era also saw the introduction of wireless remotes and DMX controls, enabling operators to integrate fog effects seamlessly into light and sound shows.

Introduction of Dry Ice Machines: In the mid-20th century, dry ice machines became popular, especially in theater. These machines used dry ice to produce a thick, low-lying fog, perfect for creating eerie and mysterious atmospheres.

Development of Haze Machines: Different from traditional fog machines, haze machines were introduced to produce a lighter, more atmospheric mist. This effect is ideal for enhancing lighting without overwhelming the stage or venue.

Eco-friendly Innovations: With growing environmental concerns, the late 20th century saw the development of eco-friendly fog fluids and machines. These innovations prioritized sustainability without compromising on fog quality.

Portable and Battery-Operated Machines: The need for mobility in the entertainment industry led to the creation of portable and battery-operated fog machines, allowing for fog effects in remote locations without the need for a power source.

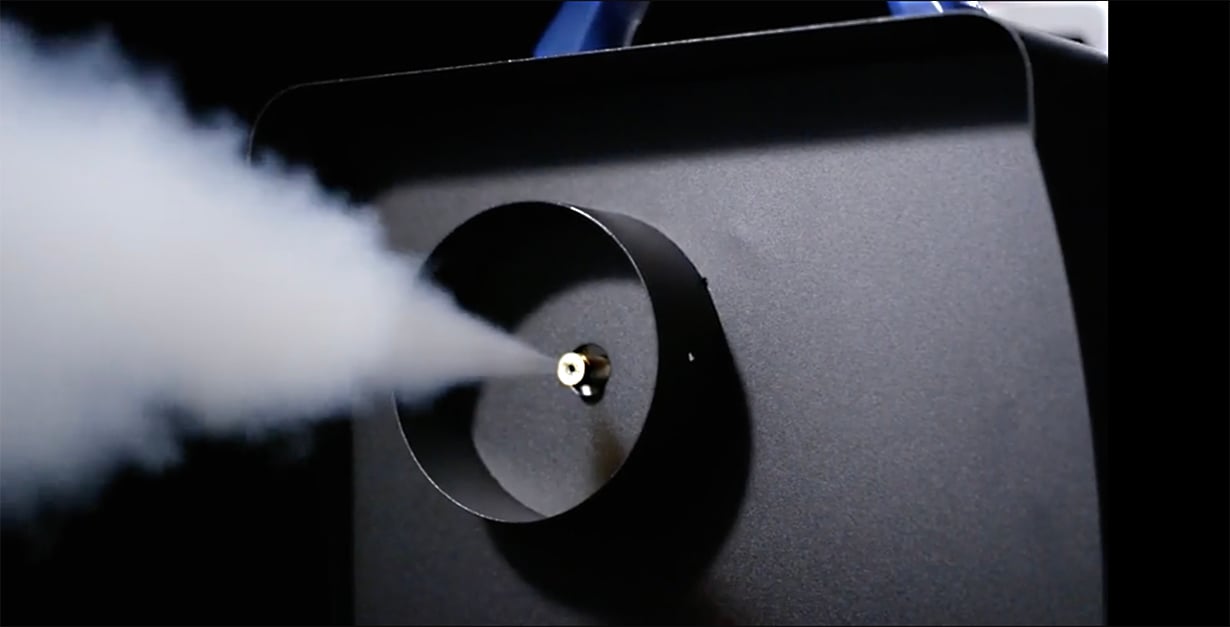

Using a professional fog machine is a much safer and more effective way to create a smoke effect on set. Let’s take a closer look at how a fog machine works.

.jpg?width=1200&height=346&name=2-Rosco-fluid-to-fog-diagram-blog%20(1).jpg) Every fog machine needs four essential elements to work:

Every fog machine needs four essential elements to work:

Different materials and components can be used to manufacture each element of the fog machine system. Changing a material, ingredient, or component of one element can affect the performance of the machine and the fog effect creates.

.jpg?width=266&height=286&name=Fog-blog-front-of-Vapour-machine-e1664414697759%20(1).jpg)

When it comes to how a fog machine works – the number one element is the heat exchanger, which is a block of metal with a heating element inside. The temperature of the heating element is controlled by a thermostat to heat the entire block to a specific temperature. As the fog fluid comes into contact with the heat exchanger, it will vaporize immediately. The most commonly used metal in fog machine heat exchangers is aluminum. While aluminum heats quickly, it also gives up its heat easily. This necessitates proper engineering between the thermostat and the controls. Some professional fog machines are designed to make as much fog as possible until the temperature of the heat exchanger is too low, at which point it will switch off the pump and reheat. Others are engineered so that as the temperature of the heat exchanger cools, the pump slows down – enabling non-stop production of fog.

.jpg?width=300&height=265&name=Vapour-Remote-300x265%20(1).jpg)

Once the heat exchanger on a fog machine has reached its peak operating temperature, something needs to switch on the pump. Professional fog machines feature multiple pump-control options. Almost every fog machine comes with a wired or wireless remote with some or all of the following features:

Most professional fog machines will also feature DMX capability that enables them to be controlled via a DMX control console. It’s also worth noting that many theme park attractions are controlled by 0-10V closed-contact controls. Some fog machines are also capable of integrating with this style of control system.

.jpg?width=300&height=227&name=Vapour-Piston-Pump-300x227%20(1).jpg)

A fog machine pump moves the fog fluid from its reservoir to the heat exchanger. The proper pump must be selected in the design of the fog machine so that it matches up to the characteristics of the heat exchanger. If the fluid is pumped too quickly, for example, too much fluid will flow across the heat exchanger and cause it to cool down too rapidly. The most commonly used pump in professional fog machines for the entertainment industry is a piston pump. Along with efficiency, the piston pump has a long performance life and provides high-volume fog output.

A professional fog fluid is water-based with a small amount of either glycol or glycerin. When the fluid hits the heat exchanger, it is vaporized in a process known as “flashing” to create quick-cooling steam. As the fluid is flashed, it expands rapidly as it exits the machine. When the vaporized fog fluid mixes with the outside air, it instantly forms an opaque aerosol – which is the effect we refer to as fog or smoke. Varying the amount of glycol/glycerin in the fluid can affect the opacity of the fog effect – the more you use, the more opaque the effect will be. Different glycols and glycerins can also create different effects, such as quick-dissipating fog, for example.

.jpg?width=600&height=600&name=Rosco-Fog-Fluid-Academy-Award%20(1).jpg) Rosco received an Academy Award® for “the development of an improved, non-toxic fluid for creating fog and smoke for motion picture production.” Rosco received an Academy Award® for “the development of an improved, non-toxic fluid for creating fog and smoke for motion picture production.” |

Using low-quality fog fluid can affect how a fog machine works. Manufacturers of professional fog fluid use deionized water to remove mineral particles that can clog up the fluid path through the heat exchanger. They also use high-quality glycols and glycerins. Rosco, for example, uses pharmaceutical-grade glycol to manufacture its range of fog fluids. When operating a fog machine, it is important to use a fog fluid that was designed specifically for that particular machine to maintain safety. Fog machines and fluids are designed as systems. Specific fluid formulas require specific temperatures for optimum vaporization. If a machine is calibrated at too low a temperature for a given fluid, the result can be “wet” fog that can leave behind a residue, or worse, spit hot fluid. If the temperature is too high, the fluid can “burn” or decompose, thus changing its chemical composition. This “burning” can create harmful byproducts |

Fog machines are versatile devices that can significantly enhance the ambiance in a variety of settings. Here's a look at some scenarios where a fog machine can be a game-changer:

Live Performances:

Film and Television Production:

Haunted Houses and Halloween Events:

Nightclubs and Parties:

Theme Parks:

Training Simulations:

Outdoor Events:

Considering the use of a fog machine for your next event or project can significantly enhance the experience for your audience. Each application offers a unique opportunity to create memorable and captivating environments.

The evolution of fog machines from their early beginnings to the modern, sophisticated devices we have today has been nothing short of remarkable. The various applications outlined in this guide showcase their versatility across different domains like live performances, film production, themed events, and more. By delving into the mechanics of how a fog machine works, we've uncovered the precise engineering that goes into creating those mystifying fog effects that significantly enhance the ambiance wherever they are employed. As we explored Rosco’s range of Vapour Fog Machines and fog fluids, it’s clear that there’s a fog solution tailored for every need. Whether you are looking to create eerie scenes, dramatic visual effects, or simply add a touch of mystery to an event, fog machines prove to be an indispensable tool in achieving the desired atmosphere.

Related Reading:

.jpg?width=1200&height=519&name=Vapour-fog-machine-family%20(1).jpg) Now that you know how a fog machine works, let’s use that context to explore Rosco’s range of Vapour Fog Machines. Every machine in the Vapour range features a piston pump, and gravity die-cast aluminum heat exchanger, but each machine is engineered differently to accommodate any budget or specification.

Now that you know how a fog machine works, let’s use that context to explore Rosco’s range of Vapour Fog Machines. Every machine in the Vapour range features a piston pump, and gravity die-cast aluminum heat exchanger, but each machine is engineered differently to accommodate any budget or specification.

Vapour PlusA compact, professional-grade fog machine capable of filling large venues with fog. Great for outdoor fog & haze effects. Mini-VA compact, portable, and affordable professional-grade fog machine. |

VapourA durable, all-purpose, professional-grade fog machine. Excellent choice for stage, photography, filmmaking & themed applications. V-HazerA professional-grade, water-based hazer that produces a flat, long-lasting haze effect for capturing light beams on set. |

.jpg?width=496&height=338&name=Rosco-liter-fog-fluids-copy%20(1).jpg)

Rosco Fog Fluid: Creates opaque fog/smoke effects with an extra-long hangtime. This green-colored fluid features Rosco’s recognizable scent that helps audience and crew members understand that the effect they’re seeing is safe and not from an actual fire.

Stage & Studio Fog Fluid: Creates an opaque effect that dissipates quickly. This is useful for low-lying chilled-fog effects, steam effects, or for creating vertical “CO2 blasts” with the Vapour Plus.

Rosco Clear Fog Fluid: Creates the same long-lasting and opaque effect as Rosco Fog Fluid, but without the colorant and scent for people who may be sensitive to those ingredients.

Rosco Light Fog Fluid: Creates a long-lasting effect that is less opaque. This is useful for those that want to create translucent haze effects using a Rosco fog machine.

V-Hazer Fluid: Designed for use in the V-Hazer, this water-based fluid creates a smooth, long-lasting haze effect that won’t leave behind an oily residue on performers, set pieces, or equipment.

Related Reading:

What is a fog machine?

How do fog machines work?

Are there different types of fog machines?

What's the difference between a fog machine and a smoke machine?

How do low lying fog machines work?

What fluid is used in fog machines?

Are fog machines safe?

Why won't my fog machine work?

Can a fog machine work outdoors?

Brittney Pecor October 24, 2022 Questions?

Prior to joining Rosco in 2018, Brittney worked as a lighting technician and light board operator in a variety of theatrical and concert venues. In her prior role as a Project Manager for our Rosco Architectural division, Brittney gained extensive knowledge of our architectural products as she built relationships with our customers. Her background in Live Entertainment and her experience with Rosco’s architectural products make Brittney a valuable resource for technicians and designers around the world.

© 2022 Rosco Spectrum