Kara Meche works for Techland – one of our dealers in Houston. Techland was exhibiting at the Space City Comic Con, and William Shatner was going to be there. With that factoid in mind, Eric Campbell, Techland Houston’s general manager, decided that he’d like to have something special for Shatner to sign – so he asked Kara to make a foam replica of the Starship Enterprise. Kara explains below how Rosco helped her glue, coat, paint and protect her starship so that Techland Houston's USS Enterprise would last for many Stardates to come.

When Eric Campbell, General Manager at Techland (and my boss), told me that we were going to be exhibiting at Space City Comic Con and that William Shatner was going to be there – we decided that we wanted to get his signature on something special. So, Eric asked me to create the USS Enterprise out of foam - and we got Captain Kirk himself to sign it!

When Eric Campbell, General Manager at Techland (and my boss), told me that we were going to be exhibiting at Space City Comic Con and that William Shatner was going to be there – we decided that we wanted to get his signature on something special. So, Eric asked me to create the USS Enterprise out of foam - and we got Captain Kirk himself to sign it!

Here is how I made it. The first thing I did was research the actual scaled dimensions (which was amazingly easy – thanks trekkers!) and then I created a step by step plan of the components that I would need to sculpt and how they fit together. I started with a 4’x4’x3” thick block of Smooth Foam that we sell here at Techland, and proceeded to carve out the saucer hull, engineering hull and the two propulsion hulls of the starship. Next, Nathan Stanaland (a local artist) and I hand sculpted additional pieces as well as sculpting, texturing and shaping the hull pieces. Together, we carved all of the details possible before gluing all the pieces together with Rosco FlexBond.

Here is how I made it. The first thing I did was research the actual scaled dimensions (which was amazingly easy – thanks trekkers!) and then I created a step by step plan of the components that I would need to sculpt and how they fit together. I started with a 4’x4’x3” thick block of Smooth Foam that we sell here at Techland, and proceeded to carve out the saucer hull, engineering hull and the two propulsion hulls of the starship. Next, Nathan Stanaland (a local artist) and I hand sculpted additional pieces as well as sculpting, texturing and shaping the hull pieces. Together, we carved all of the details possible before gluing all the pieces together with Rosco FlexBond.

Once assembled, we also double-coated the foam Enterprise with FlexBond, because after we tested several of the other coating products out there – including Rosco FoamCoat, FlexCoat and CrystalGel – the FlexBond was the only one that would keep all of our tiny details. We also noticed that with this particular type of soft-foam, most of the other coatings chipped off when we barely squeezed the foam. The FlexBond gave enough flexibility to protect our model starship - without losing all of the detailed carvings Nathan and I had labored so hard to create. Plus, even with two coats, the foam replica stayed very lightweight. The whole purpose of choosing foam in the first place was that it was lightweight. The FlexBond helped us keep it that way and made it much more durable too.

Once assembled, we also double-coated the foam Enterprise with FlexBond, because after we tested several of the other coating products out there – including Rosco FoamCoat, FlexCoat and CrystalGel – the FlexBond was the only one that would keep all of our tiny details. We also noticed that with this particular type of soft-foam, most of the other coatings chipped off when we barely squeezed the foam. The FlexBond gave enough flexibility to protect our model starship - without losing all of the detailed carvings Nathan and I had labored so hard to create. Plus, even with two coats, the foam replica stayed very lightweight. The whole purpose of choosing foam in the first place was that it was lightweight. The FlexBond helped us keep it that way and made it much more durable too.

Finally, we painted our foam Enterprise using Rosco Off Broadway Scenic Paints because I really liked the matte finish look that it gave me when I was testing it on the FlexBond coating. For the main color, we used a mixture of OB #5382 Paynes Grey and OB #5350 White with a little water. Then we used some additional Paynes Grey, White, as well as a few one oz. jars of OB Red and Black from an Off Broadway Test Kit to add in the extra details.

Finally, we painted our foam Enterprise using Rosco Off Broadway Scenic Paints because I really liked the matte finish look that it gave me when I was testing it on the FlexBond coating. For the main color, we used a mixture of OB #5382 Paynes Grey and OB #5350 White with a little water. Then we used some additional Paynes Grey, White, as well as a few one oz. jars of OB Red and Black from an Off Broadway Test Kit to add in the extra details.

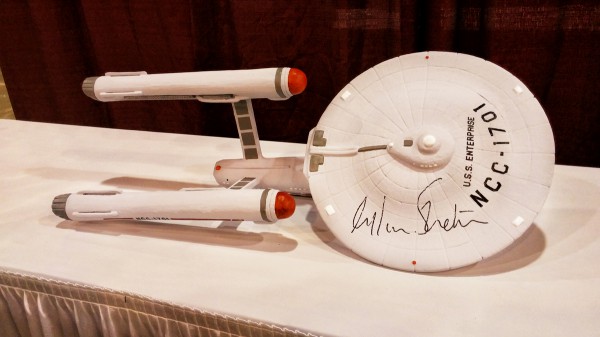

Once the Enterprise replica was complete, we took it to Space City Comic Con, where we were able to meet William Shatner in person and got him to autograph it for us. The USS Enterprise, NCC 1701 holds a place of honor in the Techland Houston showroom. Come by to see it if you’re ever in town.

Once the Enterprise replica was complete, we took it to Space City Comic Con, where we were able to meet William Shatner in person and got him to autograph it for us. The USS Enterprise, NCC 1701 holds a place of honor in the Techland Houston showroom. Come by to see it if you’re ever in town.

Save

Save