By Robert Kodadek

Robert Kodadek is President of Black Tank, Inc. a fixture design company which has recently formed a strategic partnership with Rosco for the development and distribution of LED technology. The MIRO Cube family of fixtures is the first result of this new relationship.

There’s a myth about LEDs. Many believe that they don’t get hot. But high powered LED chips, like those used in professional grade theatrical and specification grade architectural fixtures, generate a lot of heat. A 3 watt LED chip, driven at its maximum output, will generate 3 watts of heat. If the 3 watts cannot be quickly and efficiently removed from the LED chip, it will overheat, which will significantly reduce its lifetime.

Good thermal management is one of the most difficult design challenges for fixture manufacturers. It’s central to the overall fixture implementation and affects the quality of the fixture in a variety of ways. As an illustration of the range of thermal strategies in use today, consider that some manufacturers drive their LEDs at lower power levels to deal with this issue.

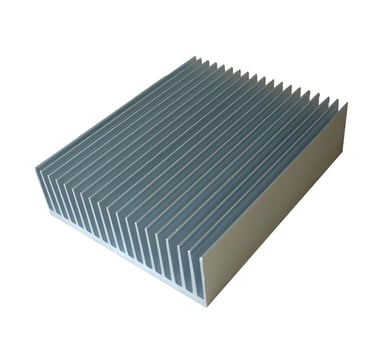

The typical thermal management strategy utilizes heat sinks fabricated from aluminum fins or integrated into the cast or metallic housing of the fixture. These methods, while sometimes effective, add significant weight and size to the fixture. To determine if a fixture utilizes this method, feel the outside of the fixture after it’s been running for a while… 50 Watts will cause a noticeable temperature rise on the surface of the housing.

The typical thermal management strategy utilizes heat sinks fabricated from aluminum fins or integrated into the cast or metallic housing of the fixture. These methods, while sometimes effective, add significant weight and size to the fixture. To determine if a fixture utilizes this method, feel the outside of the fixture after it’s been running for a while… 50 Watts will cause a noticeable temperature rise on the surface of the housing.

The Black Tank team took a different approach. We focused on cooling the LED chips directly instead of the housing.

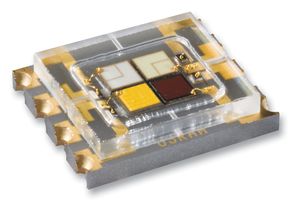

The Quad Chip from Rosco's color changing MIRO 4C

Black Tank’s patent pending thermal management technology cools the LEDs at the chip level. The proprietary technology maximizes surface area and minimizes the heat path. The result is highly efficient cooling in the minimum volume and weight possible; this results in extremely efficient operation and an extended lifetime. The technology removes 50 Watts of heat from a tiny 4” cubed form factor (comparable 50 Watt fixtures are typically 4 to 5 times this size).

Additionally, the thermal management strategy utilized on the MIRO Cube fixtures allows for removal and replacement of the LED module along with other key components. This provides a means to “future proof” the LEDs in fixtures utilizing our technology as LED chip technology progresses. For example, a MIRO Cube WNC fixture can become a MIRO Cube 4C by removing and replacing the LED module of the WNC with a 4C module.

Solid state lighting is hot right now - as a topic to discuss, a product to install and a technology to support. Thanks to the Black Tank's thermal management strategy, it's not a problem you have to solve - we've already done it for you.